LV Coil

Winding Machine

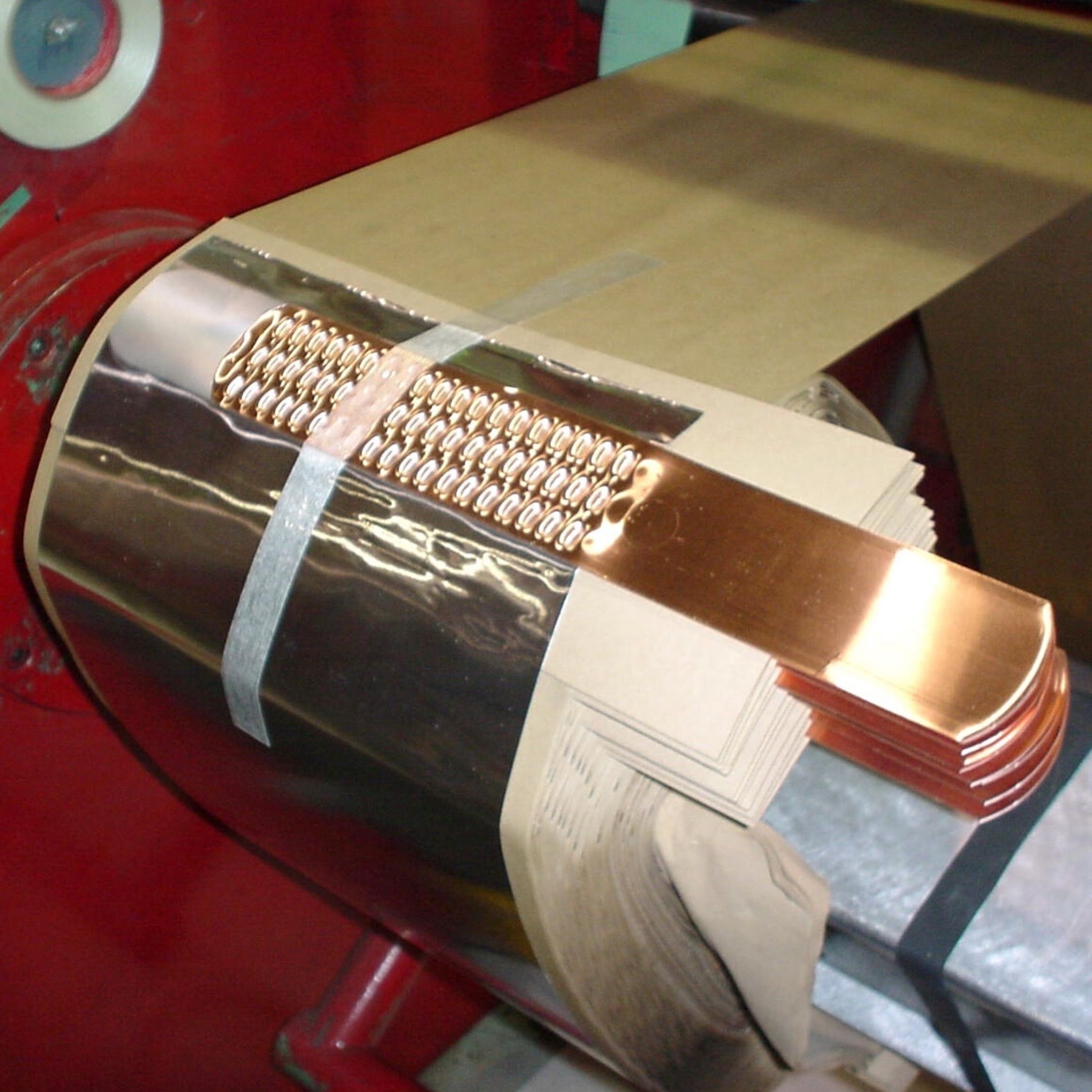

LV coil winding for 1 or 2 foil conductors with integrated cold welding for leads

LV coil winding for 1 or 2 foil conductors with integrated cold welding for leads

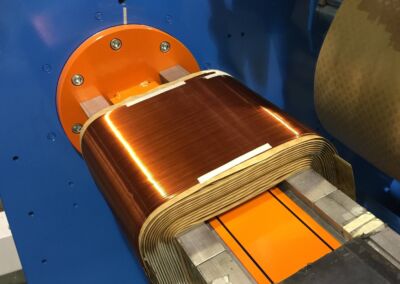

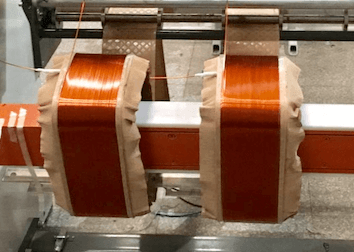

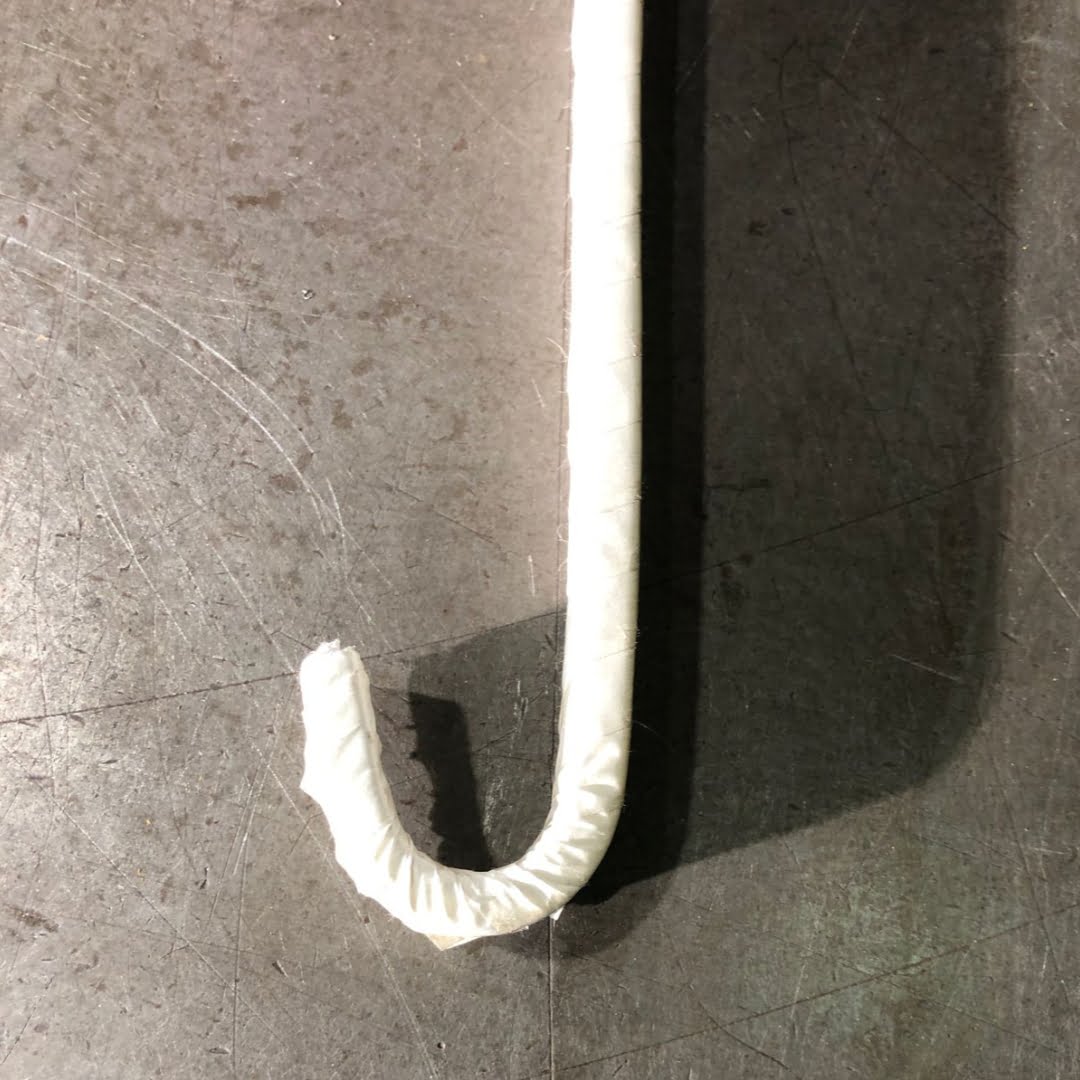

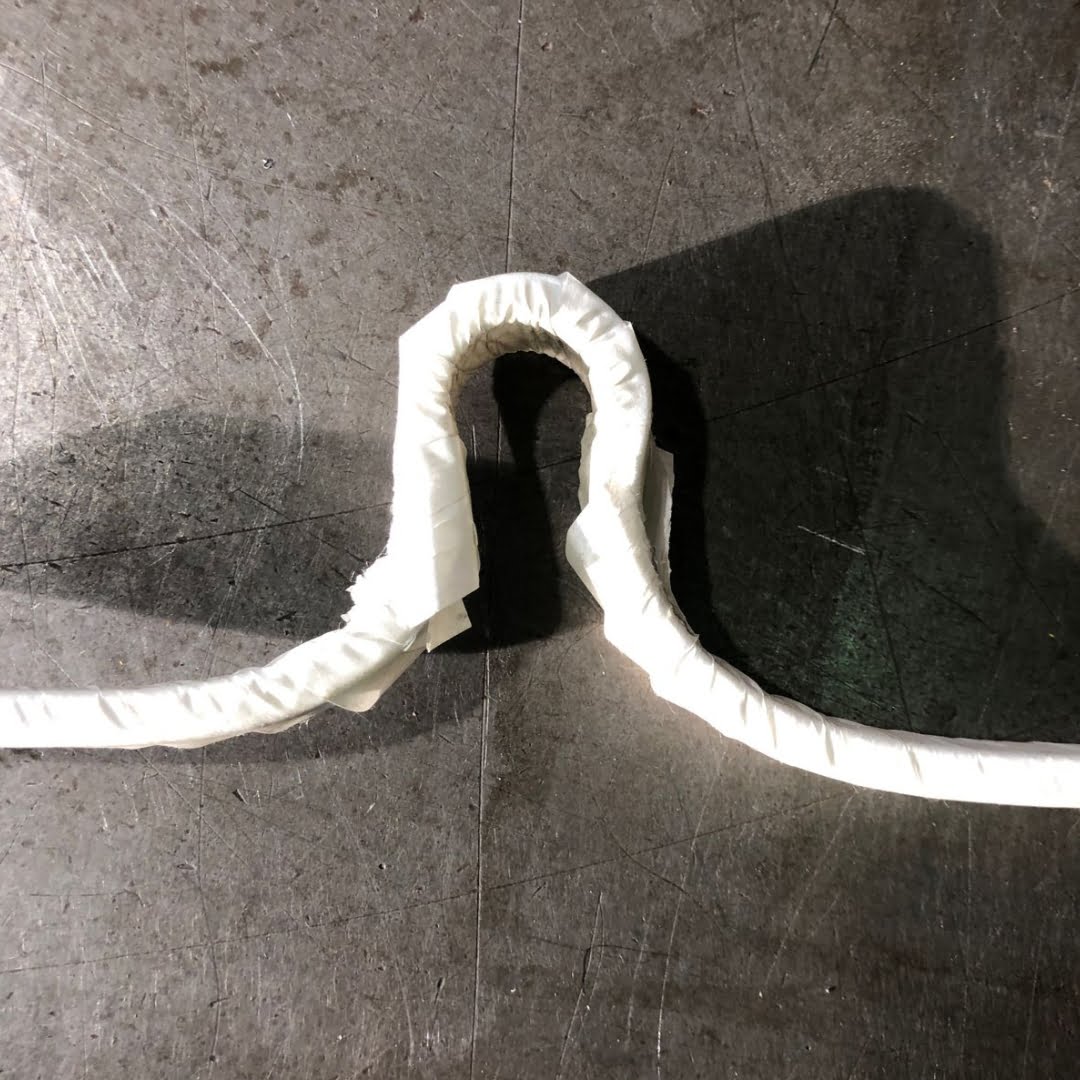

The MTM LV Coil Machines are designed to wind LV coils ranging from 100 to 3,150kVA, with one or two overlapped foils, or 2 smaller coils side by side. The foils are precisely aligned at the winding mandrel via an automatic, computer controlled laser sensor system which shifts the foil decoiler laterally. Machines are configured with cold welding technology which is a simple and easy way to join foil conductor with leads. The technology allows for the joining of aluminum to aluminum, copper to copper, and aluminum to copper. Cold welding technology works seamlessly with the coil follower arm which ensure tight coil production.

Coil follower arm in combination with constant foil tension produces smaller, tighter LV coils

Automated Tension Control

- Programmable tension control with feedback for foil conductor

- Foil alignment system ensures precise positioning of foil edge during constant tension applications

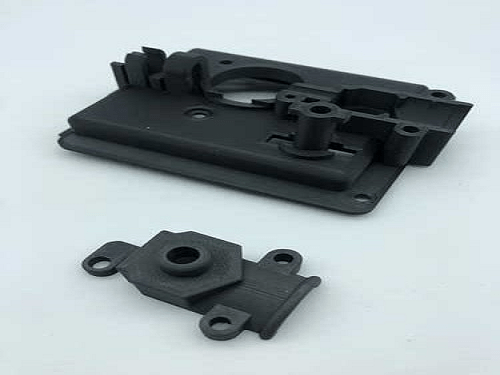

- Cold welding occurs under foil tension ensuring coil are consistently manufactured to exacting specifications

Programmable Computer Control

|

Other Features

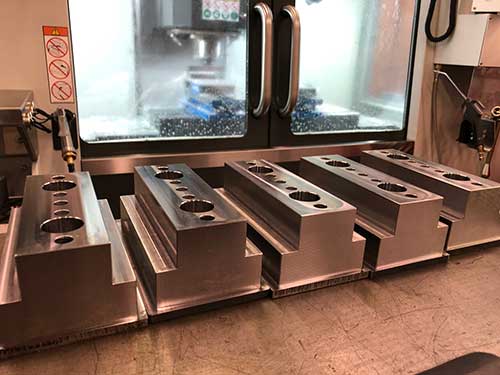

- Integrates with MTM Round or Rectangular Winding Mandrels

- Edge de-burring rollers

- Edge strip fill

- TIG Welding Integration

- HV wire winding capability (be able to complete LV and HV sections on the same machine)

LV coil winding for 1 or 2 foil conductors with integrated cold welding for leads

The MTM LV Coil Machines are designed to wind LV coils ranging from 100 to 3,150kVA, with one or two overlapped foils, or 2 smaller coils side by side. The foils are precisely aligned at the winding mandrel via an automatic, computer controlled laser sensor system which shifts the foil decoiler laterally. Machines are configured with cold welding technology which is a simple and easy way to join foil conductor with leads. The technology allows for the joining of aluminum to aluminum, copper to copper, and aluminum to copper. Cold welding technology works seamlessly with the coil follower arm which ensure tight coil production.

Coil follower arm in combination with constant foil tension produces smaller, tighter LV coils

Automated Tension Control

- Programmable tension control with feedback for foil conductor

- Foil alignment system ensures precise positioning of foil edge during constant tension applications

- Cold welding occurs under foil tension ensuring coil are consistently manufactured to exacting specifications

Programmable Computer Control

- Fully programmable control system with touch screen, userfriendly HMI and IoT ready

- Built-in UPS in the controller which allows the status to be saved prior to executing an automated, controlled shutdown

- Offline recipe creation software that can be download to machine via intranet (bar-code scanning) or USB drive.

Other Features

- Integrates with MTM Round or Rectangular Winding Mandrels

- Edge de-burring rollers

- Edge strip fill

- TIG Welding Integration

- HV wire winding capability (be able to complete LV & HV sections on the same machine)