WINDING MACHINES

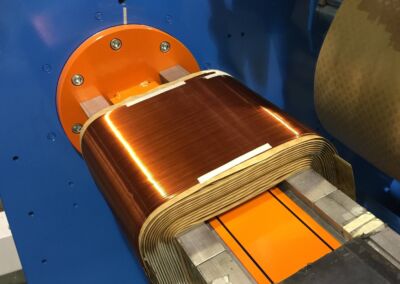

MTM offers a range of Coil Winding Machines for distribution and medium size transformer production in both semi-automatic and fully automatic format.

Machine designs are modular and can be customized to meet your specific application.

Read further to learn more.

WINDING MACHINES

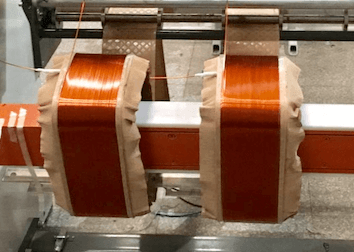

MTM offers a range of Coil Winding Machines for distribution and medium size transformer production in both semi-automatic and fully automatic format.

Machine designs are modular and can be customized to meet your specific application.

Read further to learn more.

WINDING MACHINES

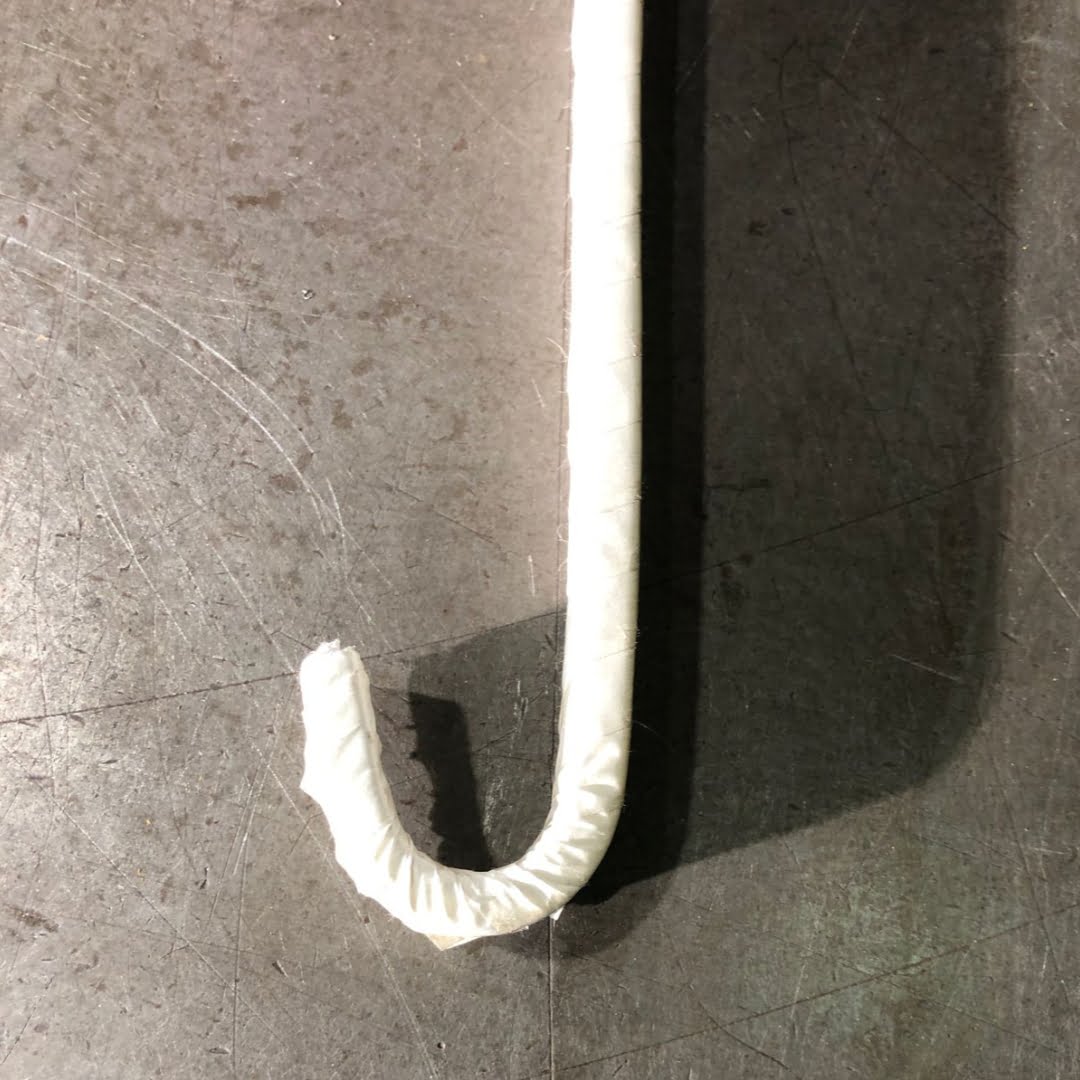

MTM offers a range of Coil Winding Machines for distribution and medium size transformer production in both semi-automatic and fully automatic format.

Machine designs are modular and can be customized to meet your specific application.

Read further to learn more.

WINDING MACHINES

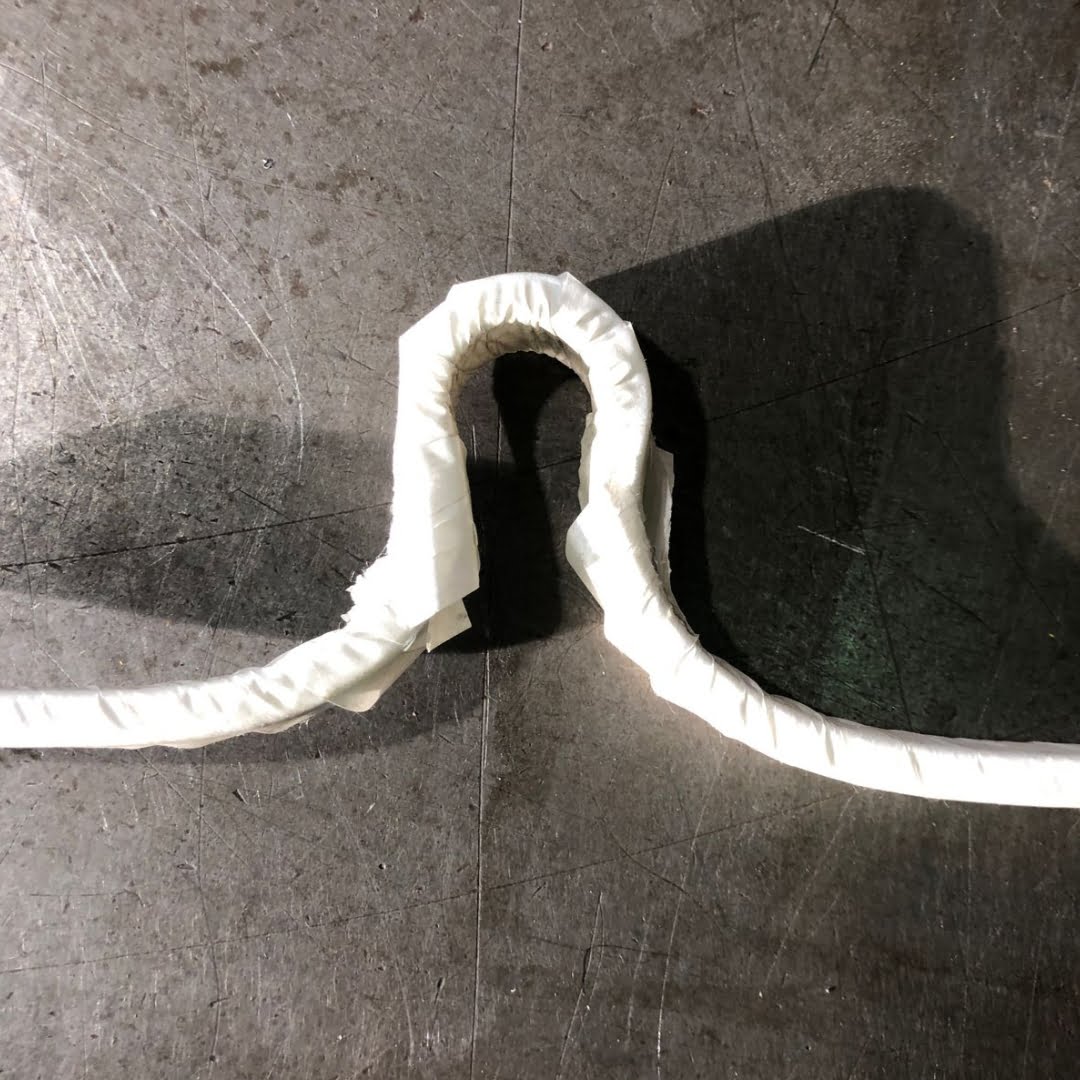

MTM offers a range of Coil Winding Machines for distribution and medium size transformer production in both semi-automatic and fully automatic format.

Machine designs are modular and can be customized to meet your specific application.

Read further to learn more.

WINDING MACHINES

MTM offers a range of Coil Winding Machines for distribution and medium size transformer production in both semi-automatic and fully automatic format.

Machine designs are modular and can be customized to meet your specific application.

Read further to learn more.

WINDING MACHINES

MTM offers a range of Coil Winding Machines for distribution and medium size transformer production in both semi-automatic and fully automatic format.

Machine designs are modular and can be customized to meet your specific application.

Read further to learn more.

WINDING MACHINES

MTM offers a range of Coil Winding Machines for distribution and medium size transformer production in both semi-automatic and fully automatic format.

Machine designs are modular and can be customized to meet your specific application.

Read further to learn more.

WINDING MACHINES

MTM offers a range of Coil Winding Machines for distribution and medium size transformer production in both semi-automatic and fully automatic format.

Machine designs are modular and can be customized to meet your specific application.

Read further to learn more.

WINDING MACHINES

MTM offers a range of Coil Winding Machines for distribution and medium size transformer production in both semi-automatic and fully automatic format.

Machine designs are modular and can be customized to meet your specific application.

Read further to learn more.

WINDING MACHINES

MTM offers a range of Coil Winding Machines for distribution and medium size transformer production in both semi-automatic and fully automatic format.

Machine designs are modular and can be customized to meet your specific application.

Read further to learn more.

WINDING MACHINES

MTM offers a range of Coil Winding Machines for distribution and medium size transformer production in both semi-automatic and fully automatic format.

Machine designs are modular and can be customized to meet your specific application.

Read further to learn more.

WINDING MACHINES

MTM offers a range of Coil Winding Machines for distribution and medium size transformer production in both semi-automatic and fully automatic format.

Machine designs are modular and can be customized to meet your specific application.

Read further to learn more.