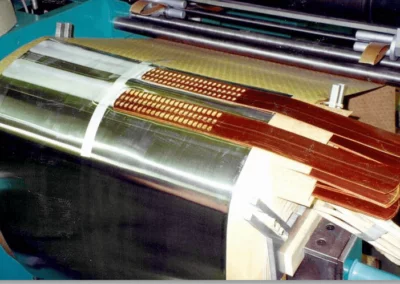

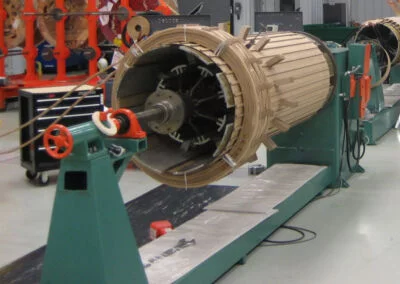

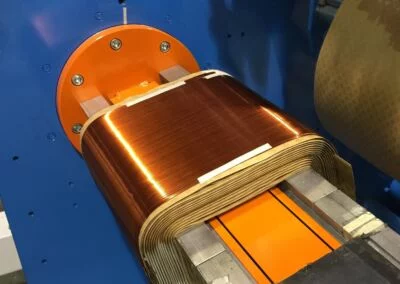

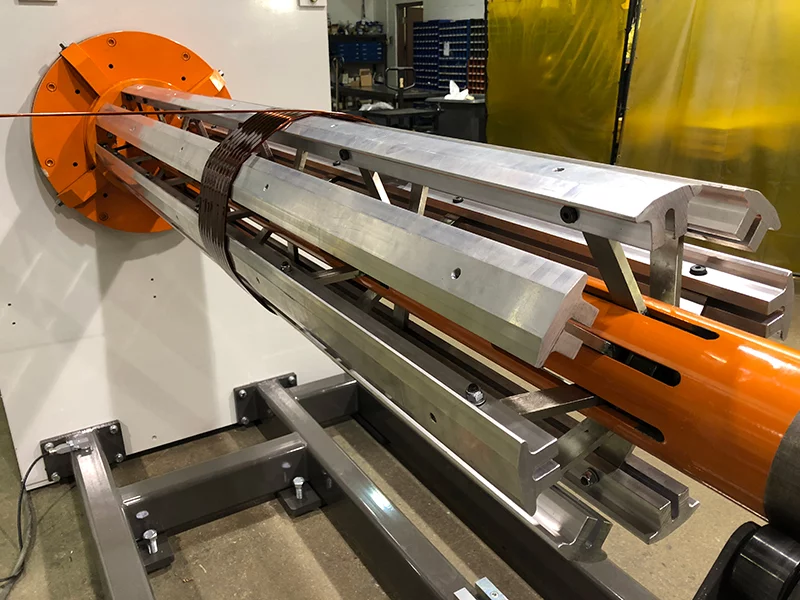

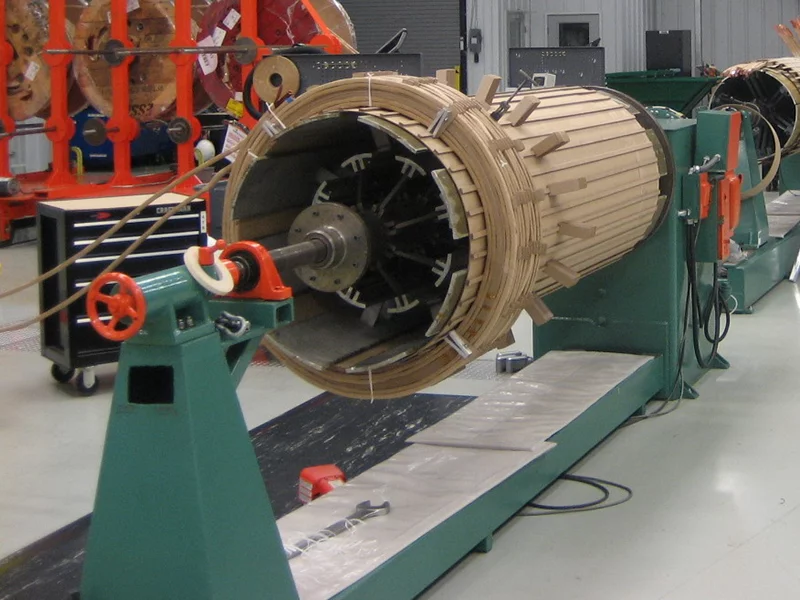

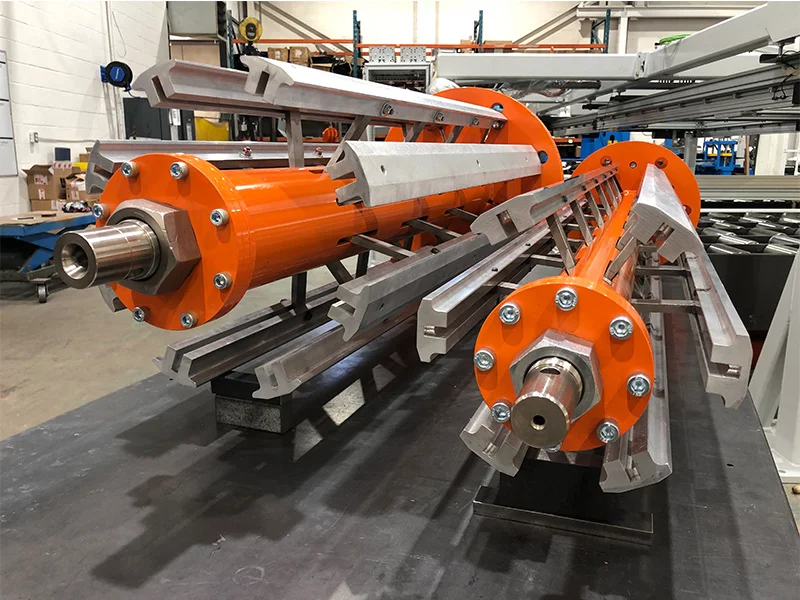

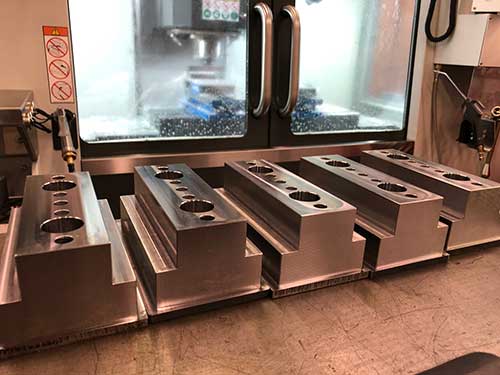

TOOLING

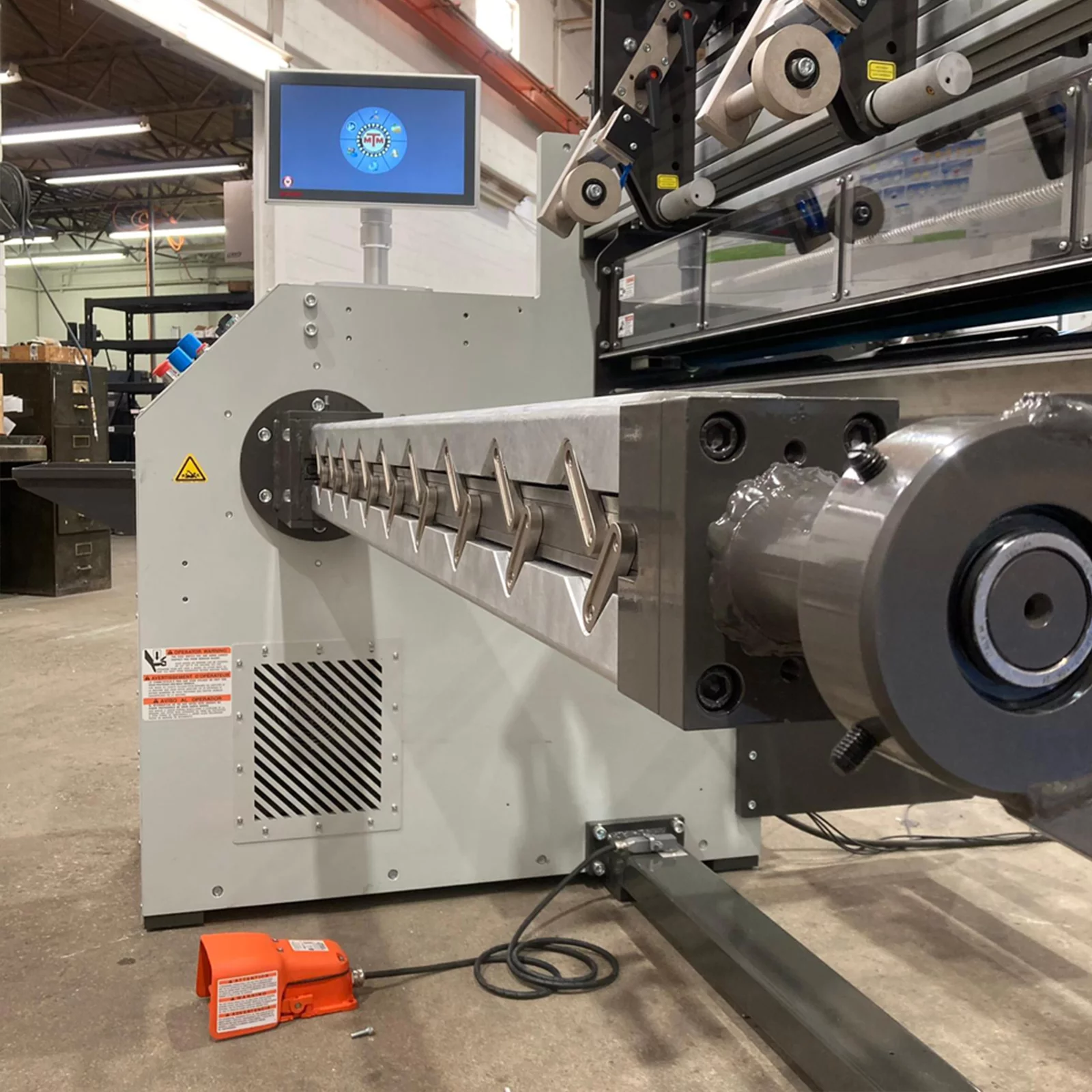

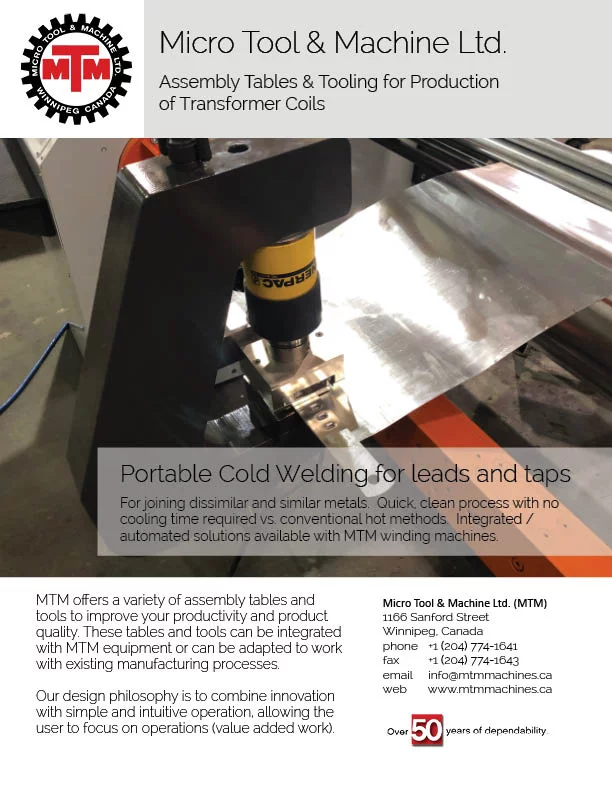

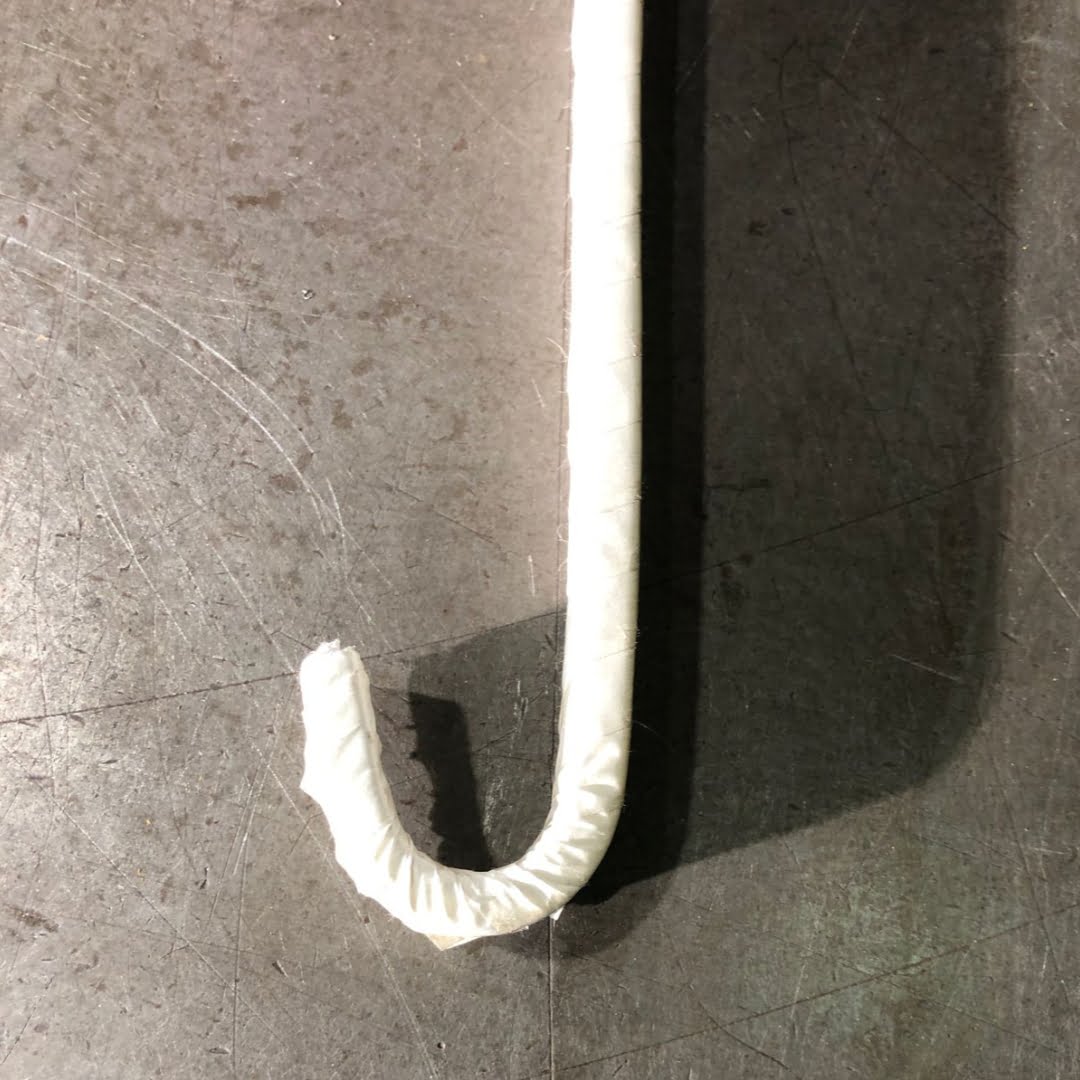

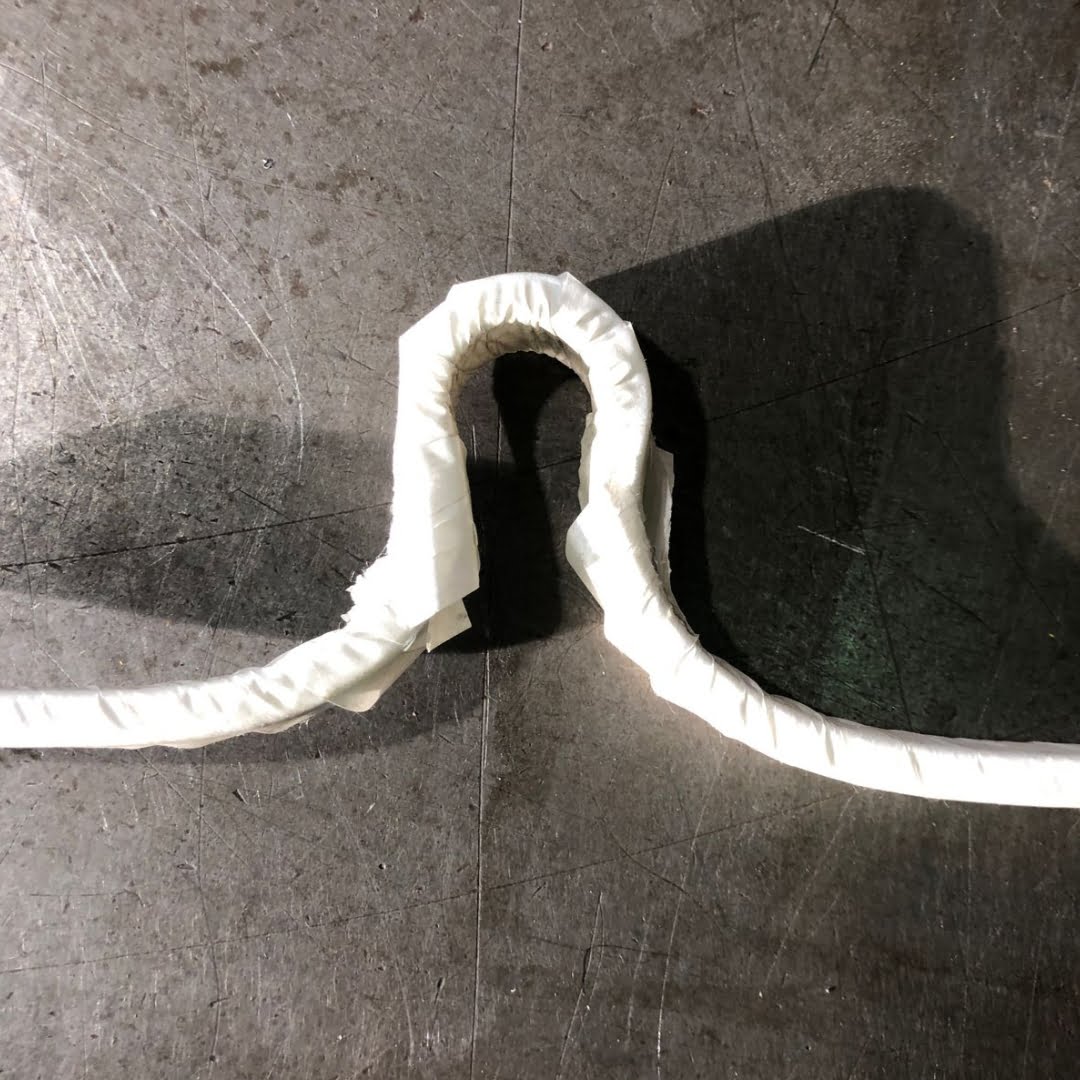

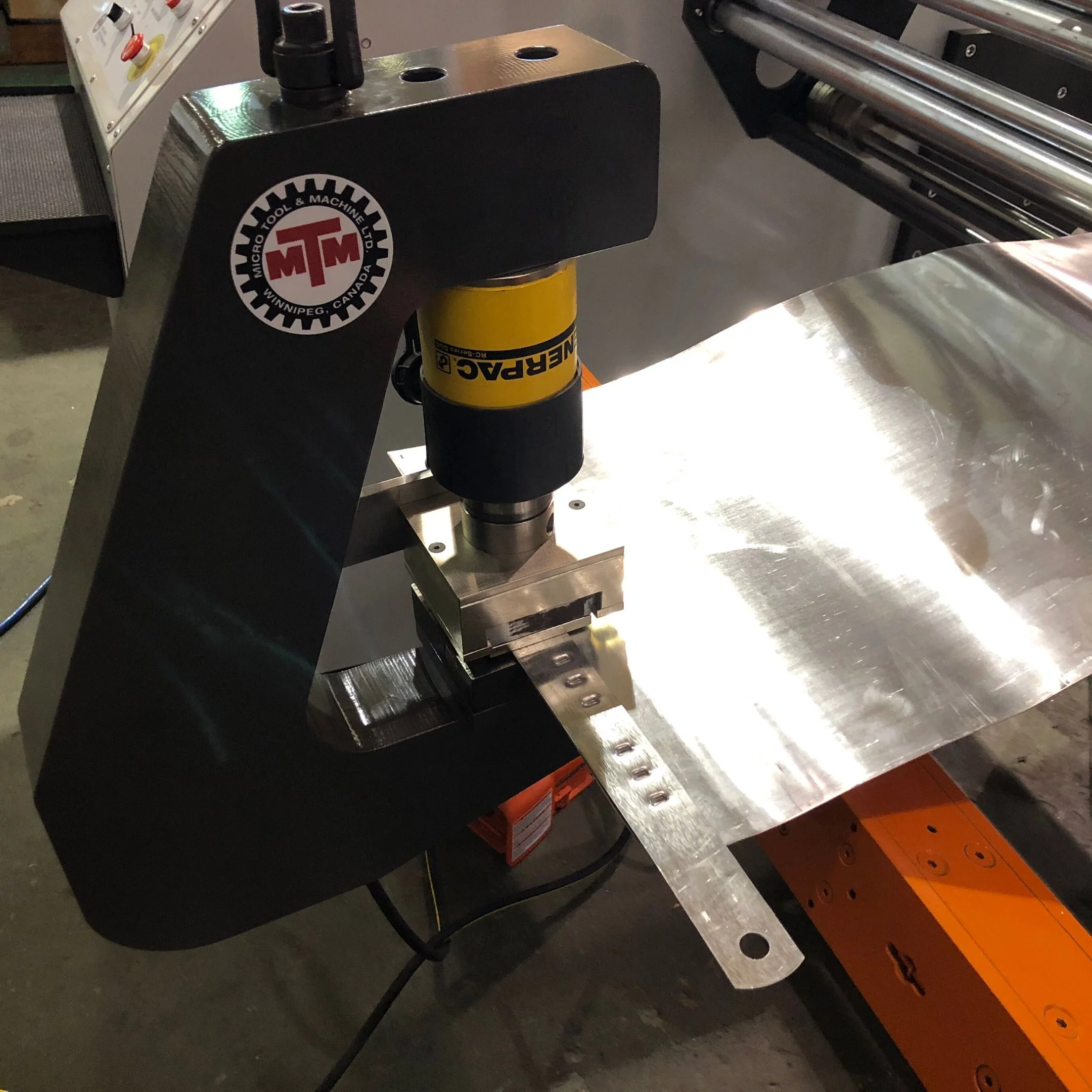

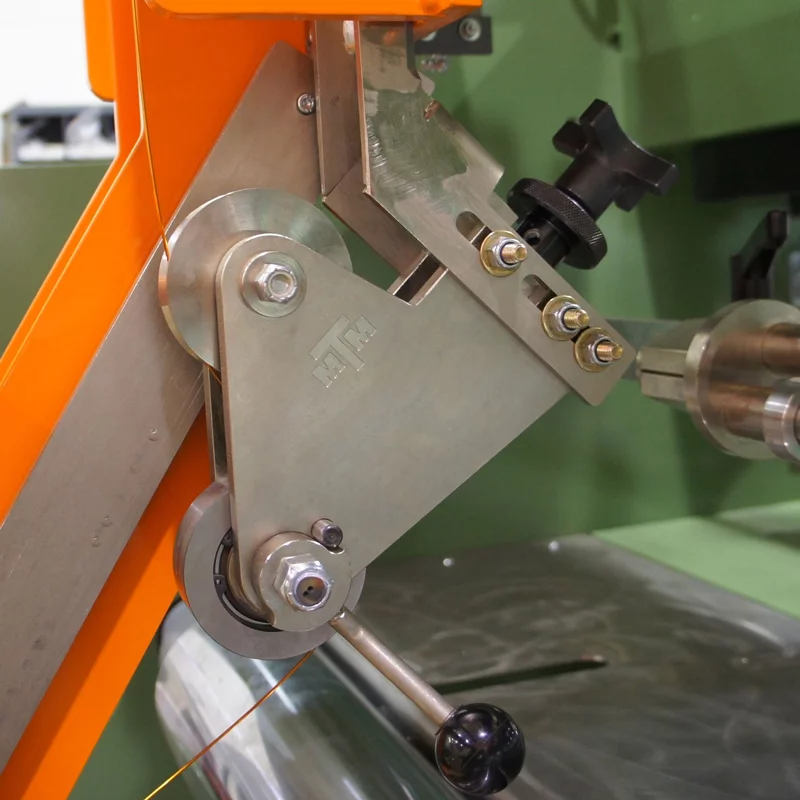

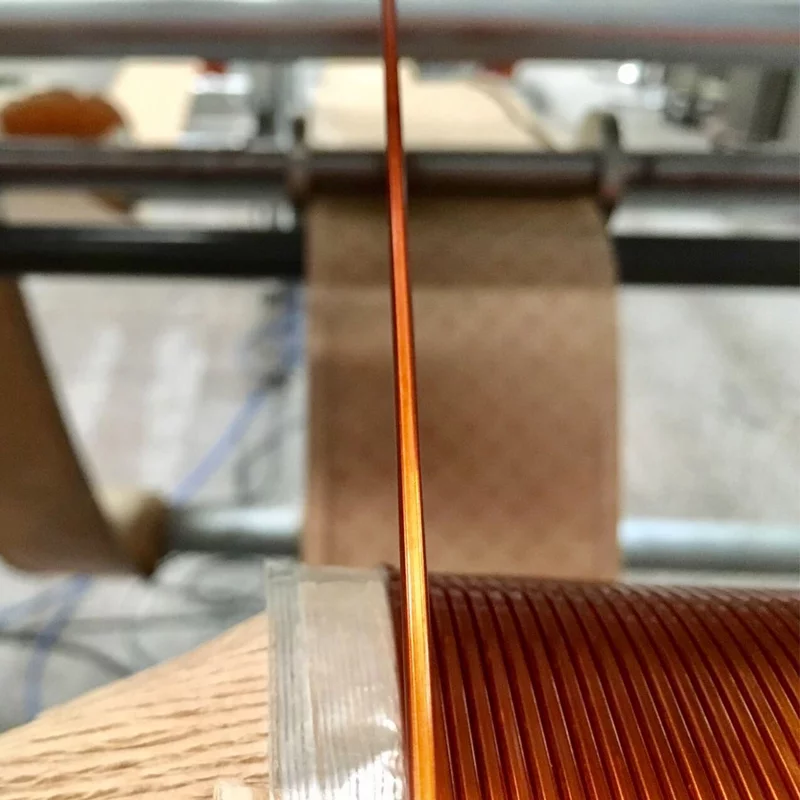

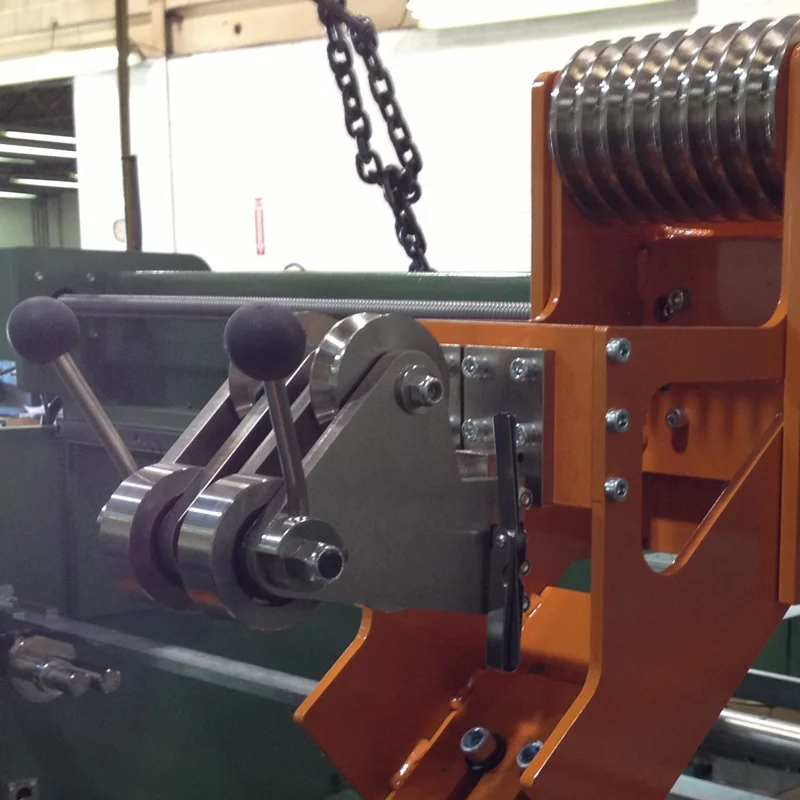

Tooling is an important part of any manufacturing process. MTM can provide a wide range of tools to meet your requirements and elevate your production.

Solutions are available as stand alone, portable tools, or tools that can be integrated into your existing machines.

Read further to learn more.